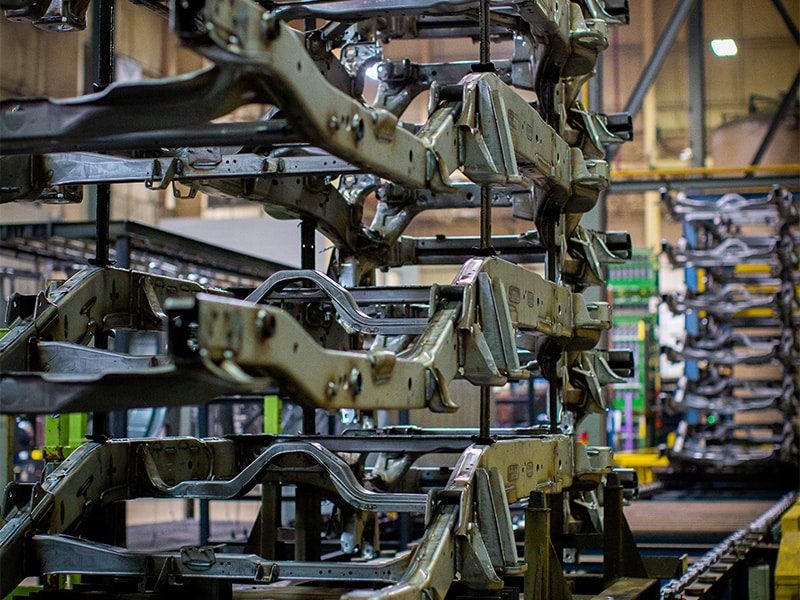

State-of-the-Art, High-Capacity Electrocoat System

We offer exceptional flexibility in electrocoating products.

Size and a crane-based transfer mechanism set our state-of-the-art electrocoat system apart from many others. Accommodating a 33,500-gallon e-coat tank and six 9,100 capacity cranes, our system is one of the largest non-OEM systems in the nation. The system size provides exceptional flexibility in electrocoating products ranging from whole antique car bodies to small drill bits.

System Capacity

1,320

square feet

Surface Area Per Pallet

3,200

lbs

Maximum Pallet Load

2.5

hours

Full-Cycle Time

- System package envelope – 5’ wide, 19.2’ long, and 10.8’ high

- Black paint/resin coating and all non-aluminum metals

79,000

square feet

Processing Area

22,500

gallon

11 Pretreatment Tanks

33,500

gallon

1 Electrocoat Tank

33,000

gallon

3 Post-Electrocoat Rinse Tanks

- Large processing area – 58’ clear ceiling height and 79,000 square feet of space

- Two 130° caustic cleaning stages

- Drainage tilting above tanks

- PPG ED6451HE Enviro-Prime 2000®, lead-free, cationic electrocoat

- 385° overhead oven and contiguous lower cooling tunnel

- Pretreatment and electrocoating system – manufactured by George Koch Sons

- Cranes – 6 programmable cranes

- Zinc phosphate conditioning

- Full tilting inside electrocoat tank

- 15-stage cathodic electrocoat system – 11 pretreatment stages and 4 electrocoat stages

Shipping & Receiving

6

total

Freight-Level Docks

5

total

Street-Level Docks

32

feet

Warehouse Clear Ceiling Height